Home > products > Valve > Ball Valves

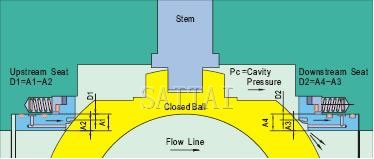

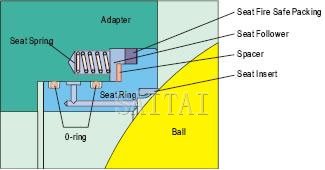

Seat Sealing Feature

a) Upstream seat: The seats can be moved slightly along the valve axis, upstream line pressure acting on the

seat area (A1) does not equalize against on the seat area (A2).The differential force in the area (D1) pushes

the seat tightly against the ball surface resulting in a tight effective seal. (Fig.1)

b) Downstream seat: When the body cavity pressure is lower than the downstream pressure, the net pressure

difference acting over area (D2) pushes the downstream seat tightly against the ball surface creating a positive

seal. (Fig.1)

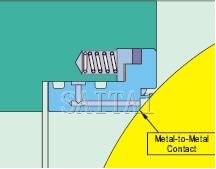

Self Relieving Seat

When the body cavity pressure exceeds the downstream seat spring preloaded force, the differential force in the area (D2) pushes the down stream seat away from the ball, the body cavity pressure will automatically relieve. And then the seat returns to the ball under spring action. (Fig.1)

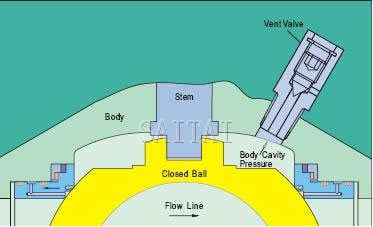

Double Block and Bleed

When the ball is in the closed position, each seat of the ball valve can cut off the medium independently on the upstream and downstream side to realize double-block functions. The body cavity are isolated from each side of the valve, the body cavity pressure could be released through the vent valve. (Fig.2)

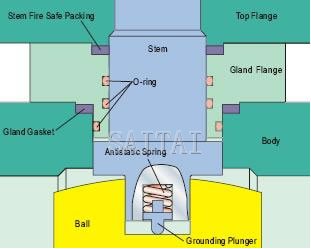

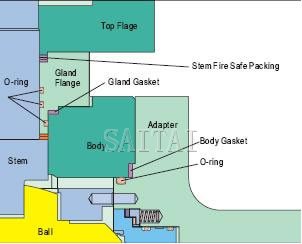

Blow-out Proof Stem

The stem with integral T-type shoulder, supported by gland, can be guaranteed not to be blow-out by the medium even if at abnormal risen pressure in the cavity. (Fig.3)

Anti-Static Device

During turning of the stem to opening and closing the valve, static electricity is easily caused by sparks generated by friction. Antistatic devices, assembled by a spring & a grounding plunger, assure the electrical continuity, between ball and stem, stem and body, to prevent the possible risk of fire or explosion.(Fig.3)

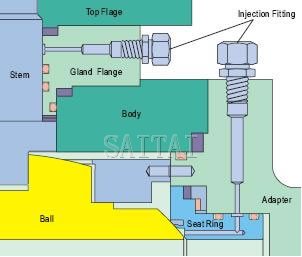

Emergency Sealant Injection System

For 6 inch and larger trunnion mounted ball valves, or small valves on request, special sealants may be injected through a sealant injection fittings that are located on the adapter and the gland to obtain emergency sealing, in case of seat or stem O-ring are damaged and leakage occur by fire or other accidental. Fittings also internally installed a second check valve t o provide backup sealing. (Fig.4)

Fire safe Design

a) Internal leakage prevention

When seat insert, O-ring and spacer are damaged in a fire, the line pressure and the seat preloaded spring push

the seat metal lip into the ball surface to cut off the line fluid and prevent the internal leakage to reach

fire-safe purpose. Besides, the seat graphite packing can prevent fluid leakage from between the valve body and

the seat. (Fig.5)

b) External leakage prevention

A combination of O-ring and graphite gasket o n body / adapter connection, body / gland connection, and stem /

gland joint, can prevent the external leakage. When O-rings are damaged after a fire, body gasket, gland gasket,

and stem packing, can reach sealing function and prevents external fluid leakage.

(Fig.6)

Trunnion Mounted Ball Valves Related Products

Next:Forged Steel Trunnion Mounted Ball Valves

Catalog:ball valve