Home > products > Valve > Ball Valves

Design Feature

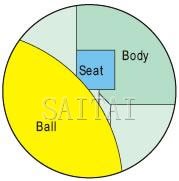

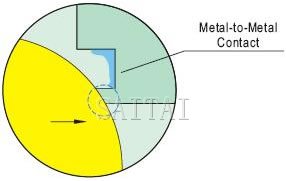

Remy floating ball valves fire safe is designed in accordance with API 607 & API SPEC 6FA. When non-metal resilient seats are destroyed in a fire, the upstream medium pressure push the ball into the downstream metal seat lip to cut off the line fluid and prevent the internal leakage due to a secondary metal-to-metal seals

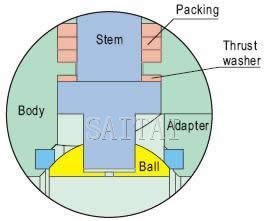

The stem is designed with integral T-type shoulder to provide blow-out proof effectively. It is internally inserted as the backseat function to assure stem sealing safety at all pressures.

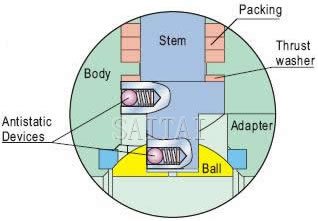

Antistatic devices between ball & stem and stem & body are assembled by a spring & a stainless steel ball, which ensure all metal valve parts are grounding.

With more and more concern for environment protection in the whole world, low emission valve will be widely used. Low emission valve can prevent poisonous, flammable, explosive medium from leaking to pollute the air; and also important that low emissions valve can minimum fugitive emission of VOC to help solve the problem of "Global Warming".

Low Emission Packing

Because of frequent opening and closing of the valve, normal graphite granule can be drawn by the stem, which will cause leakage. Eemy designed low emissions valve use special low emissions packing to ensure the seal of stem. The cone packing is made of expanding graphite in die-formed rings and has features of heat resistance, less stress relaxation and low creep. With this special structure, it allows for a low-friction on rotary & rising stem valve, therefore providing the stabilized sealing performance for long cycle life. For low temperature service, the standard V shape PTFE packing rings are used for low emissions control.

Controlled Stem and Stuffing Box Finish

Its also a key point to control the stem and stuffing box finish when machining. The stem is made by cold rolling and stem surface finish is controlled by Ra0.4, which can reduce friction for stem moving and ensure the graphite to fill and migrate into the stems micro scratches, and function as a lubricant to reduce stem leakage. The stuffing box surface is controlled within Ra1.6 and Ra3.2 for better holding of the packing ring and results in a better sealing performance.

Live Loaded Gland Flange

In normal case, valve packing is tightening by gland and gland bolting. During the service, the gland load retention will be reduced by long time pressure from medium, which will cause possible leakage with loosened packing. Enine designed low emissions valve use a set of Belleville springs installed on each gland stud to provide a continuous compressive force on gland, which guarantees permanent load retention for the stem packing to avoid fugitive emissions.

Floating Ball Valves Related Products

Next:Cast Steel Floating Ball Valves

Catalog:ball valve